Did you know that concrete, steel, and aluminum cause 23% of global emissions? This shows how urgent it is to use sustainable building methods. When looking at eco-friendly materials, it’s key to know the impact of timber, concrete, and steel.

The construction sector could cut emissions by 18% by 2030 if it used more bio-based materials. This change is happening in some places. For instance, France now needs all new public buildings to have at least 50% timber or natural materials.

Mass timber, a new wood product, is becoming popular in building. It’s used in about 38% of wood products in buildings worldwide. A 2020 report suggests that we could use timber for 90% of new buildings by 2050 with good forest management.

When choosing sustainable building materials, it’s important to know the good and bad of each. Timber helps absorb carbon, while concrete and steel are strong and last long. Knowing these facts helps you make better choices for your green building projects.

Key Takeaways

- Concrete, steel, and aluminum contribute to 23% of global emissions

- Shifting to bio-based materials could reduce construction emissions by 18% by 2030

- France mandates 50% timber or natural materials in new public buildings

- Mass timber is used in 38% of wood products in the building sector

- Proper forest management could enable timber use in 90% of new constructions by 2050

- Each material – timber, concrete, and steel – has unique sustainability features

Environmental Impact of Timber

Timber is a sustainable building material with big environmental benefits. Its unique properties make it a great choice for eco-friendly construction projects.

Carbon Sequestration in Timber

Trees take in carbon dioxide from the air and store it in their wood. This process, called carbon sequestration, keeps going even after trees are cut down. Mass timber buildings can act as carbon sinks, lowering the carbon footprint of construction.

Sustainable Forestry Practices and Certifications

Responsible forest management is key for timber’s environmental benefits. Sustainable forestry ensures trees are replanted, keeping forests healthy and diverse. Look for certifications from groups like the Forest Stewardship Council (FSC) when buying timber.

Embodied Energy of Timber Production

The energy needed to make timber is less than for concrete or steel. This means timber uses less energy to harvest, process, and move. Lower energy use means fewer greenhouse gas emissions during production.

Durability and Longevity of Timber Structures

Modern timber construction has made wood structures more durable. Cross-laminated timber (CLT) can make big slabs up to a foot thick and as large as 18-feet-long by 98-feet-wide. These engineered wood products are as fire-resistant and strong as concrete and steel buildings.

| Aspect | Timber | Concrete | Steel |

|---|---|---|---|

| Carbon Sequestration | High | Low | None |

| Embodied Energy | Low | Medium | High |

| Durability | Good | Excellent | Excellent |

| Renewability | Yes | No | No |

While timber has many environmental benefits, it’s crucial to focus on sustainable sourcing and responsible forest management. This ensures we get the most out of timber in construction.

Environmental Impact of Concrete

Concrete is key in building, but it has a big environmental cost. The way cement is made is a big source of greenhouse gases, making up about 8% of global CO2 emissions. This shows we need better, greener options for concrete.

Carbon Emissions from Cement Production

The emissions from making cement are a big worry. The high heat needed for making cement releases a lot of CO2. For every ton of cement made, almost a ton of carbon dioxide is released into the air.

Advances in Low-Carbon Concrete

The industry is working hard to make greener concrete. New ideas aim to cut down concrete’s carbon footprint without losing its strength. Ideas include using different binders, adding recycled materials, and improving how mixes are made.

Recycled Concrete and Aggregate Materials

Using recycled concrete is becoming more popular. By breaking down and reusing old concrete, we can save resources and cut down on waste. This method helps protect the environment and reduces the need for new materials.

Durability and Lifecycle of Concrete

Even though concrete starts with a big environmental cost, it has long-term benefits. Its lasting quality can make up for some of the initial emissions. Well-made concrete can last for many years, reducing the need for frequent repairs.

| Aspect | Traditional Concrete | Low-Carbon Concrete |

|---|---|---|

| CO2 Emissions | High | Reduced by 30-50% |

| Recycled Content | Limited | Up to 50% |

| Lifespan | 50-100 years | Similar or improved |

As construction evolves, finding a balance between concrete’s benefits and its environmental impact is crucial. Research and new ideas in green alternatives and recycling are promising for a greener future in building.

Environmental Impact of Steel

Steel production is key in the construction world, but it has big environmental effects. Knowing how steel production energy and recycling work is vital for green building.

High Energy Use in Steel Production

Steel making uses a lot of energy. It involves mining iron ore and heating it up a lot. This method makes steel have a big carbon footprint, with 1.8 tonnes of CO2 for every tonne of steel.

Recyclability of Steel

Steel is great because it can be recycled. Recycling steel cuts down its carbon footprint. Many steel products are made from recycled materials, saving energy and resources.

Advances in Low-Emission Steel Production

The steel industry is working on making steel production cleaner. They’re using green energy and improving how they make steel. These changes aim to lower steel’s carbon footprint without losing its strength.

Structural Benefits and Longevity of Steel Buildings

Steel buildings last a long time, which is good for the environment. They are strong and durable. This means they can last longer, reducing the need for new buildings or repairs.

“Steel allows for rapid assembly from component parts, significantly reducing on-site construction time, which may be advantageous for projects with time constraints.”

Steel’s environmental impact is big, but it’s also recyclable and durable. With responsible use, steel can be a good choice for green construction.

Comparing Embodied Carbon of Timber, Concrete, and Steel

Choosing the right building materials affects your project’s carbon footprint. Embodied carbon calculation helps compare timber, concrete, and steel. Let’s look at how these materials compare and ways to lessen their environmental impact.

Calculating Embodied Carbon: Timber vs. Concrete vs. Steel

Embodied carbon varies among materials. Steel usually has the highest carbon footprint, followed by concrete. Timber often has the lowest. But, sourcing and manufacturing can change this ranking.

| Material | Net CO2 Emissions (kg CO2/kg) |

|---|---|

| Concrete | 0.95 |

| Cement | 1.0 |

| Steel (virgin) | 1.30 |

| Mass Timber | Significantly lower |

The Impact of Material Choices on Carbon Footprint

Your choice of materials greatly affects a building’s carbon footprint. For example, using reused steel can cut embodied carbon by 14% compared to recycled steel. It’s 43% lower than typical steel. Mass timber structures can reduce carbon emissions like removing 550 cars from the road for a year.

Reducing Embodied Carbon Through Material Innovation

Material innovation is crucial for lowering embodied carbon. Mass timber production emits less carbon than concrete or steel. It also speeds up construction by 20-25% and cuts on-site energy use. The concrete and steel industries are working on lower-carbon alternatives to meet sustainability goals.

Carbon Offsetting Strategies in Material Selection

To offset carbon, consider local sourcing to cut shipping emissions. Design choices also matter. Shorter spans can reduce costs by 40% and embodied carbon by 35%. Choosing buildings with larger footprints over tall structures can lower embodied carbon by 19-26%.

By carefully weighing these factors, you can make informed decisions. This helps minimize your project’s carbon footprint while meeting structural needs.

Renewable and Non-Renewable Resources: Timber vs. Concrete vs. Steel

Building materials are key to green construction. We’ll look at the differences between renewable timber and non-renewable concrete and steel.

Timber as a Renewable Resource

Timber is a renewable choice if harvested right. Sustainable harvesting keeps forests healthy while meeting needs. It can cut a building’s carbon footprint by up to 45% compared to concrete and steel.

Concrete and Steel as Non-Renewable Resources

Concrete and steel use non-renewable resources. The iron and steel market is over $1 trillion. These materials have benefits like high strength and durability.

The Role of Recycling in Concrete and Steel

Recycling is key for concrete and steel. The steel industry is moving to near-zero emissions. This matches the U.S. goal to cut greenhouse emissions by 50-52% by 2030.

Sustainable Harvesting vs. Resource Extraction

Timber harvesting balances forest health with production. Concrete and steel aim to lessen extraction harm. The mass timber market is growing fast, showing a move towards sustainability.

| Material | Renewable | Recyclable | Carbon Footprint |

|---|---|---|---|

| Timber | Yes | Partially | Low |

| Concrete | No | Partially | High |

| Steel | No | Highly | Medium |

The construction world is changing. The choice between renewable and non-renewable materials is crucial. Each has its own benefits and challenges, shaping green building’s future.

Energy Efficiency in Timber, Concrete, and Steel Structures

Building materials are key to energy efficiency. Timber, concrete, and steel each have special qualities that affect a building’s performance. Let’s see how these materials help make buildings sustainable and energy-efficient.

Insulation Properties of Timber vs. Concrete vs. Steel

Timber is known for its natural insulation. It’s much lighter than concrete, cutting down foundation mass by 30-45% compared to steel and concrete. This lightness helps timber buildings use less energy.

Thermal Mass of Concrete for Passive Solar Design

Concrete is great for passive solar design because of its high thermal mass. It soaks up heat during the day and gives it out at night. This helps keep the inside temperature steady, cutting down on heating and cooling needs.

Timber Frame Homes for Low-Energy Designs

Timber frame homes are becoming more popular for their energy efficiency. The Carbon 12 building in Portland, Oregon, is the tallest commercial mass timber structure in the U.S. It can store about 2,000 metric tons of CO2, acting as a carbon sink.

Integrating Renewable Energy with Each Material Type

Each material can work well with renewable energy. Timber is perfect for supporting solar panels because of its lightness. Steel can hold wind turbines, and concrete’s thermal mass is great for geothermal systems. Using these materials with renewable energy makes structures very efficient and sustainable.

“Mass timber is gaining popularity due to its faster on-site assembly, predictability, quiet construction process, strength compared to steel, and potential fireproof qualities.” – Sustainable Home Magazine

Health and Well-Being Impacts: Timber vs. Concrete vs. Steel

Building materials shape our living spaces. The choice between timber, concrete, and steel impacts health and well-being. Let’s look at how these materials affect indoor air quality, biophilic design, acoustic comfort, and construction safety.

Indoor Air Quality and Material Off-Gassing

Wood structures often improve indoor air quality. Unlike concrete and steel, timber releases fewer harmful chemicals. This makes wood a healthier choice for living environments.

Steel and concrete may need extra treatments to match wood’s air quality.

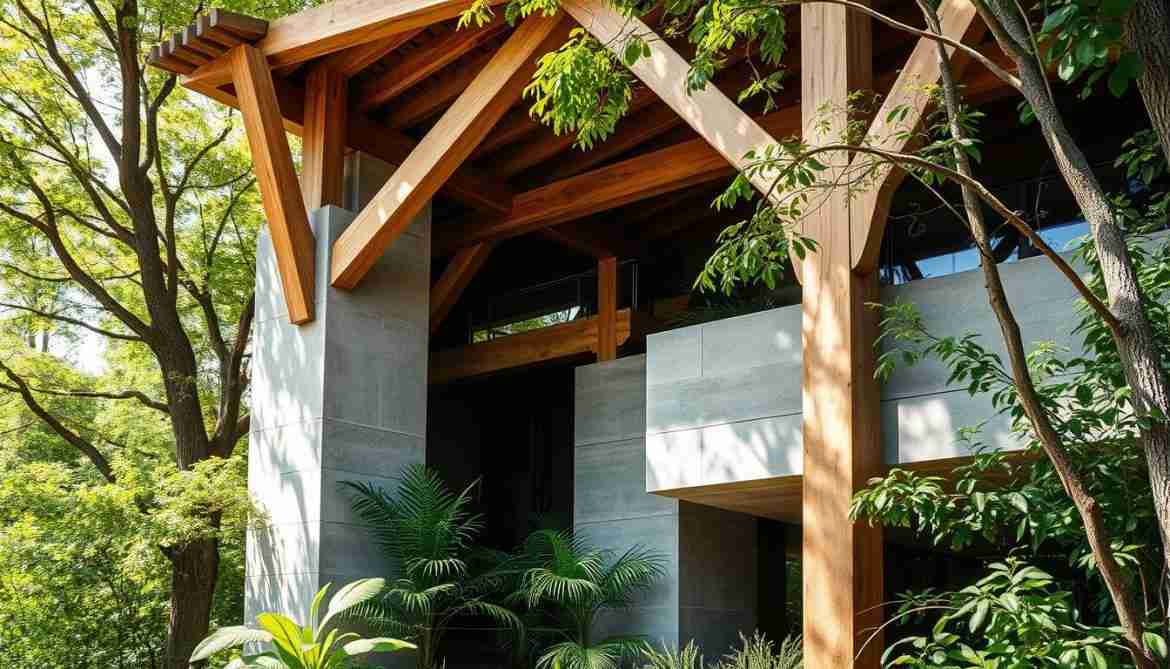

Natural Aesthetics and Biophilic Design

Timber is great for biophilic design, connecting us with nature. Its warm, natural look creates a calming atmosphere. Concrete and steel, while versatile, often need extra elements to achieve a similar effect.

Using wood in construction can boost well-being and reduce stress in living spaces.

Acoustic and Thermal Comfort Differences

Each material offers unique acoustic comfort properties. Wood naturally absorbs sound, creating a quieter environment. Concrete provides excellent sound insulation between floors.

Steel structures may need additional treatments for optimal acoustic performance. For thermal comfort, concrete’s mass helps regulate temperature, while wood offers natural insulation.

Construction Safety Considerations

Safety during construction varies with each material. Timber construction sites are often quieter and cleaner. Steel structures require a smaller workforce, reducing on-site risks.

Concrete poses challenges with dust and heavy equipment. Each material demands specific safety measures to protect workers.

| Material | Indoor Air Quality | Biophilic Design | Acoustic Comfort | Construction Safety |

|---|---|---|---|---|

| Timber | Excellent | High | Good | Clean, quiet sites |

| Concrete | Fair | Low | Excellent | Dust, heavy equipment |

| Steel | Fair | Low | Fair | Smaller workforce |

Choosing the right building material involves balancing various factors. Wood offers significant advantages in health and well-being aspects. Yet, concrete and steel have their strengths in specific applications.

Consider your project’s unique needs when selecting materials for optimal health and comfort outcomes.

Cost Comparisons: Timber, Concrete, and Steel

When planning a construction project, it’s key to know the cost of different materials. Timber, concrete, and steel each have their own costs. These costs affect both the initial cost and the cost over time.

Initial Construction Costs

The material you choose greatly affects the cost. Steel structures need special work, which can be expensive. Timber is often cheaper, especially for smaller buildings.

Concrete is seen as a cost-effective choice, especially for foundations and parts that carry weight.

Lifecycle Costs and Maintenance

Looking at lifecycle costs is important for a good return on investment. Steel is quick to build and easy to fix, which can save money. It can also be reused.

Concrete is built to last, needing little upkeep. Timber needs more care but can save on energy costs because it insulates well.

Return on Investment for Sustainable Choices

Choosing sustainable materials can save money in the long run. Timber is popular for its low energy use and carbon footprint in eco-friendly construction. Steel is recyclable, which helps its sustainability.

Concrete is durable, which makes it sustainable, even though it has a high carbon footprint at first.

Cost-Effective Sustainable Innovations

New materials are changing construction costs and making it more sustainable:

- Timber: Cross-laminated timber (CLT) lets us build taller wood structures

- Concrete: Self-healing concrete means less upkeep

- Steel: New steels need less material

| Material | Initial Cost | Maintenance | Sustainability |

|---|---|---|---|

| Timber | Low to Medium | Medium | High |

| Concrete | Low | Low | Medium |

| Steel | High | Low | Medium to High |

By considering these points, you can make smart choices. These choices balance costs, lifecycle costs, and sustainability in your projects.

Future Innovations in Timber, Concrete, and Steel for Sustainability

The construction world is changing fast, with a focus on green materials. Mass timber is at the forefront, offering big environmental wins. It can cut CO2 emissions by 30% to 50% compared to old concrete and steel buildings.

Mass Timber Construction and Cross-Laminated Timber (CLT)

Mass timber is changing building methods. It’s not just good for the planet; it’s also very flexible. Timber buildings are much lighter than concrete or steel ones.

This lightness lets us build taller and faster. The Northlake Commons project in Seattle showed a big carbon savings. It used mass timber instead of concrete, cutting carbon by 46%.

Green Concrete: Carbon Capture and Utilization

Green concrete tech is getting better to cut down its carbon footprint. New ways to capture and use carbon are making concrete production greener. These steps aim to lessen the harm concrete does to the environment.

Steel Production Using Renewable Energy

The steel industry is turning to renewable energy to cut emissions. Clean energy and hydrogen-based methods are being explored. This move is key to making steel production less carbon-heavy.

Hybrid Structures Using Timber, Concrete, and Steel

The future of building is in hybrid structures that use timber, concrete, and steel. These designs combine the best of each material while being kinder to the planet. Sustainable Home Magazine says these hybrids offer longer spans and quicker builds. They’re becoming a hit in eco-friendly designs everywhere.